Cathodic protection

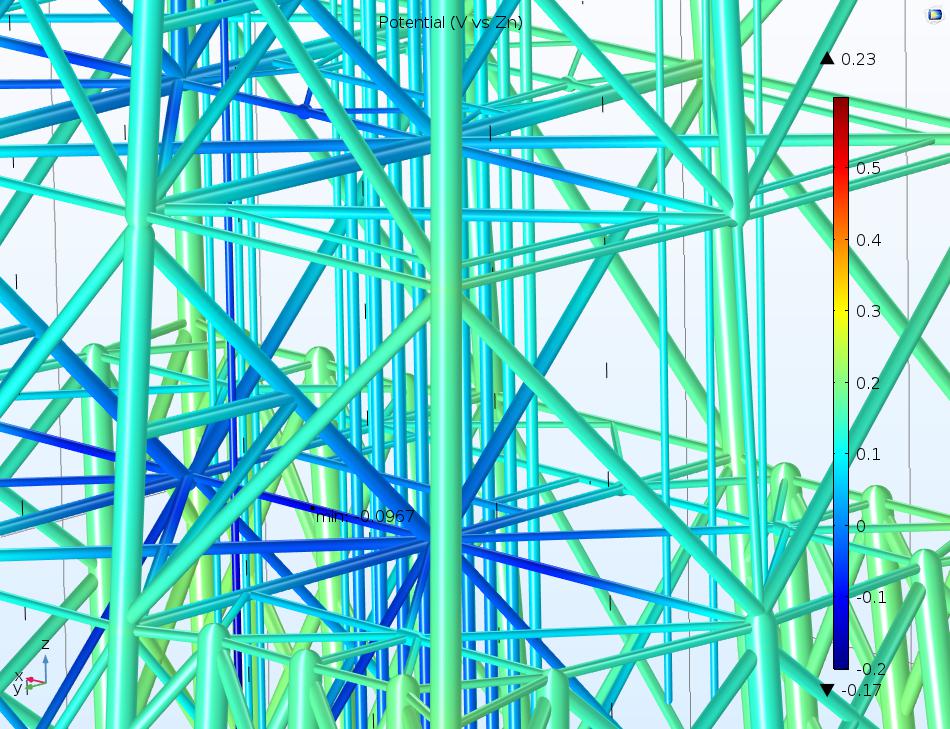

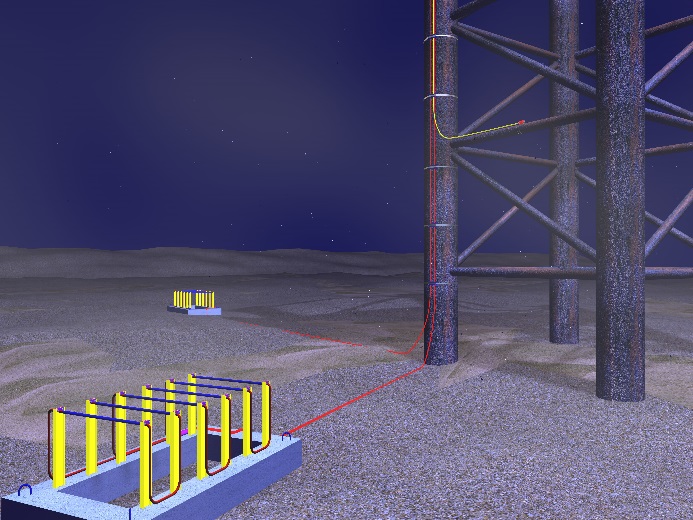

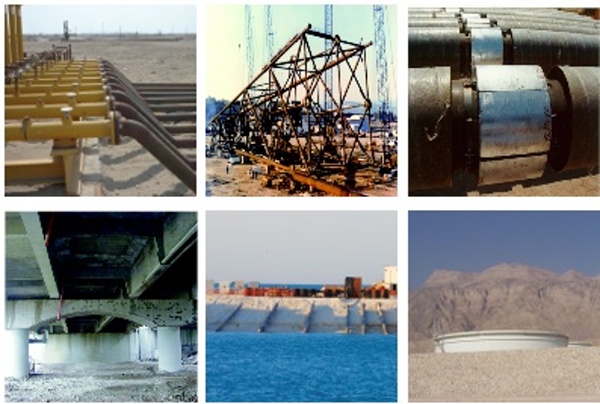

Cescor provides complete cathodic protection services, covering: feasibility studies, site surveys, detail design packages, materials procurement, erection supervision, start-up and commissioning, periodical controls and maintenance. Cathodic protection systems - impressed current and galvanic anodes - are supplied using first quality materials procured through a network of qualified manufacturers.

Fiscal Code GB 258765259

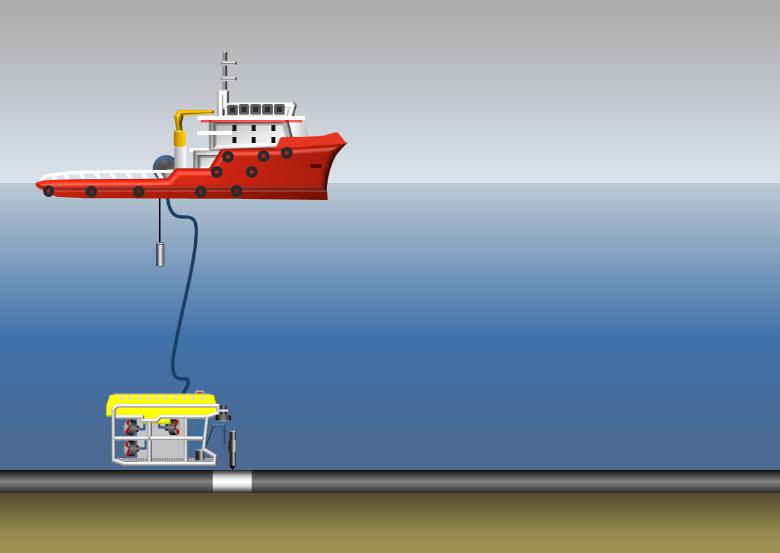

CESCOR provides underwater cathodic protection inspections, including proprietary and patented instrumentation to be installed on ROVs or handled by divers, including – probes, electronics, software – and EN 15257 certified personnel for the execution of inspections.

CESCOR provides underwater cathodic protection inspections, including proprietary and patented instrumentation to be installed on ROVs or handled by divers, including – probes, electronics, software – and EN 15257 certified personnel for the execution of inspections.